Green roof system | east-west system

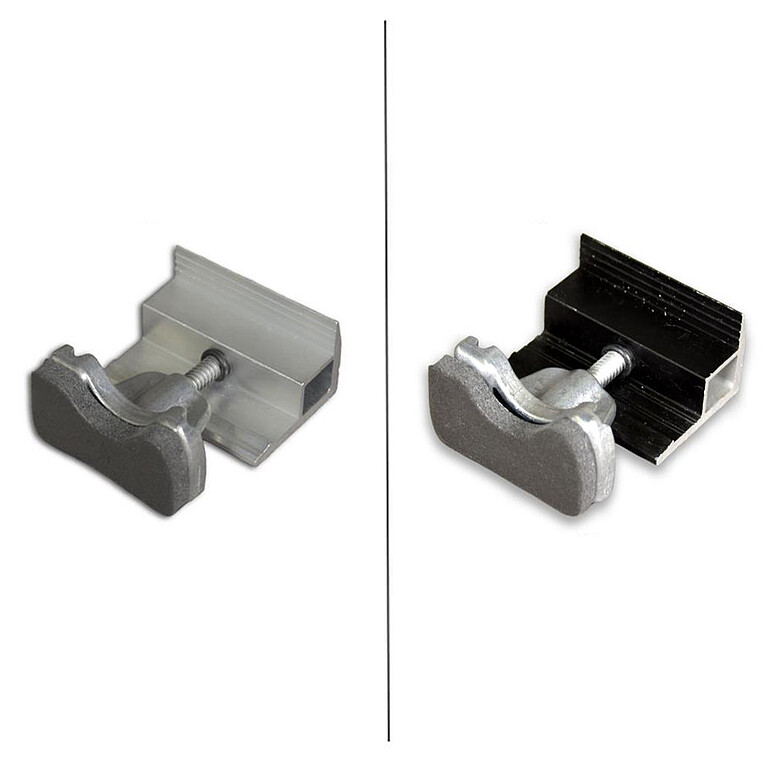

Clamping system with modules installed in portrait

- Suitable for a wide range of green roofs

- Retention effect: Time-delayed water run-off relieves the sewage system – especially during heavy rainfall

- Natural cooling of the ambient temperature and the PV system

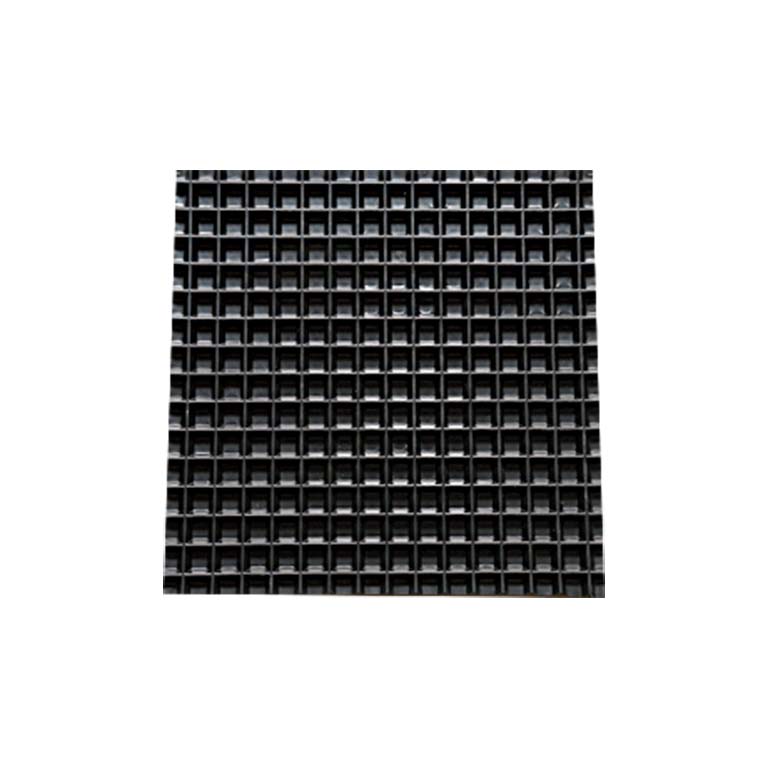

- Sustainable production made in Germany from recycled plastic

Your benefits

Efficient use of space thanks to 10° module inclination and portrait mounting

Large substrate plates provide sufficient space for ballasting

Wind tunnel tested aerodynamics

Sufficient distance to the roof surface for plant growth and sliding snow

Components

Components

Click on the + Icons to see components of this mounting system.

Downloads

More information about the green roof mounting system

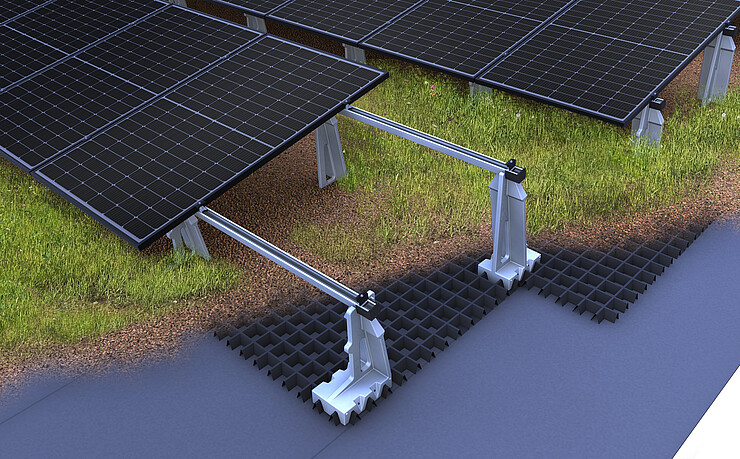

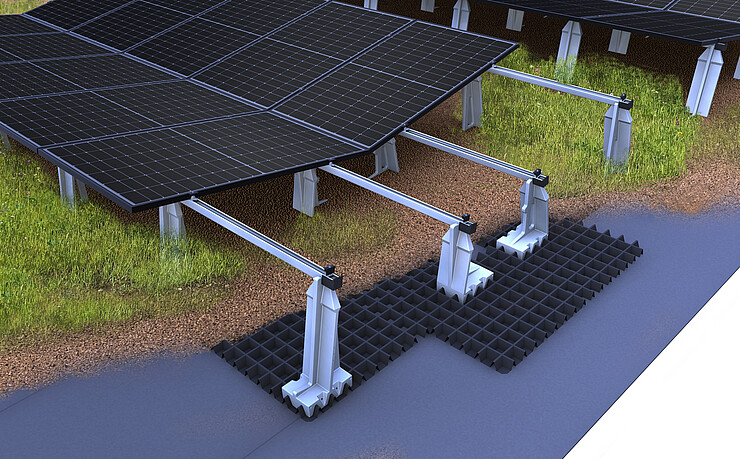

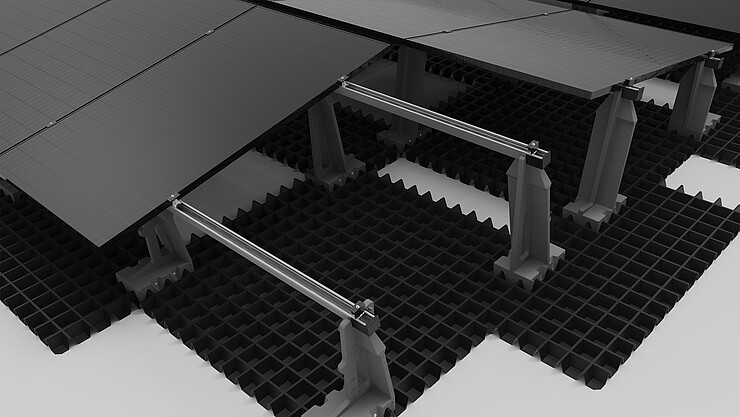

With our green roof mounting system East-West, you make maximum use of the surface area of your flat roof: through different layouts with the same components, not only East-West, but also butterfly and South orientations are possible. The electricity production is thereby distributed more evenly throughout the day. The mounting system with an inclination of 10° ) is a very safe and stable system for flat roofs - and is also easy and quick to set up. On the roof, the mounting system offers sufficient space for ballasting due to large-area substrate plates, as well as a sufficient distance to the roof surface for plant growth and slipping snow. The water storage volume of the sheet favours the retention effect.

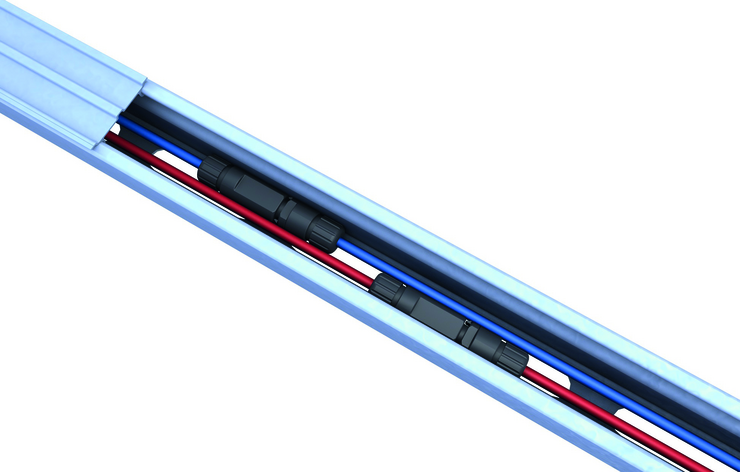

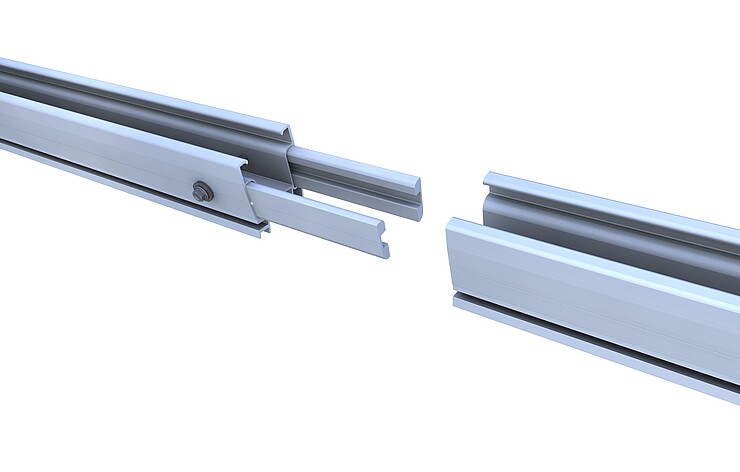

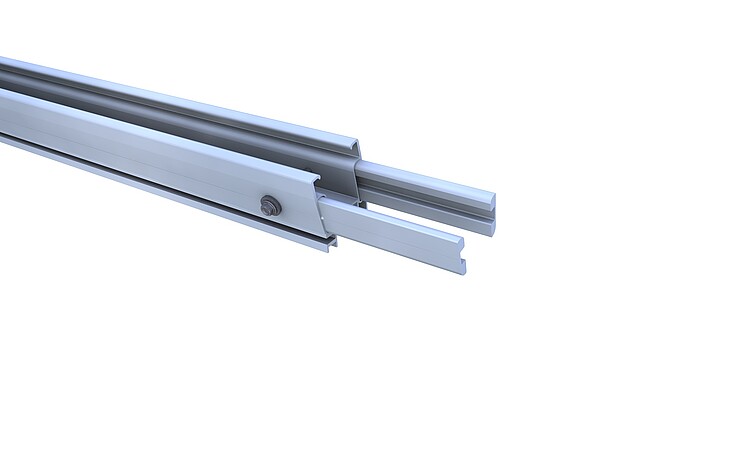

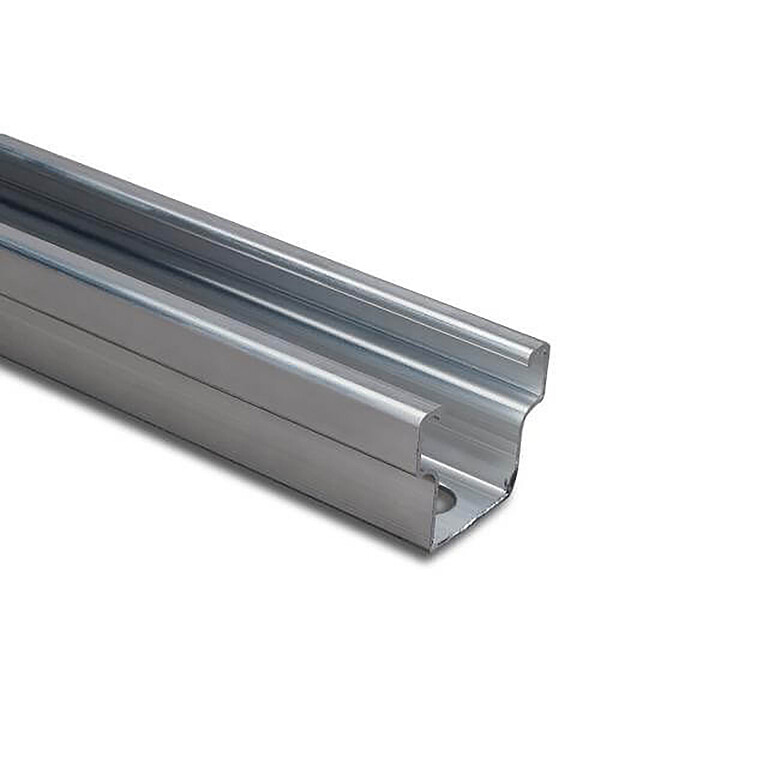

The PV mounting system allows the roof surface to be optimally utilised through landscape module mounting. A narrow service aisle nevertheless ensures convenient access. The panels are clamped to the provided lateral fastening points and fewer rails are required than with horizontal module layout. The panels, made of recycled plastic, are installed in an overlapping manner. This mounting feature allows for quick and easy installation of the substructure without measuring - guaranteed error-free! The cable duct is already integrated into the c-rail and does not have to be laid additionally. The very few parts simplify storage and logistics.